Call: 07971459788

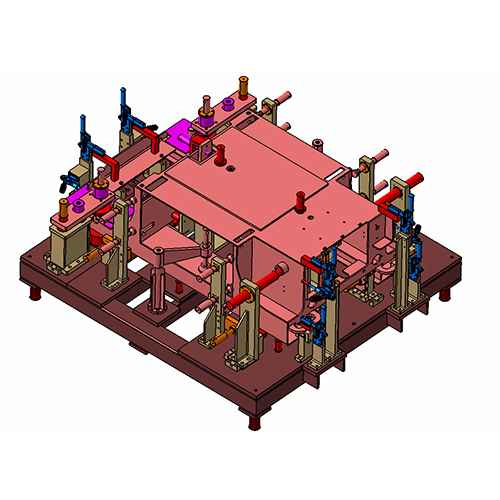

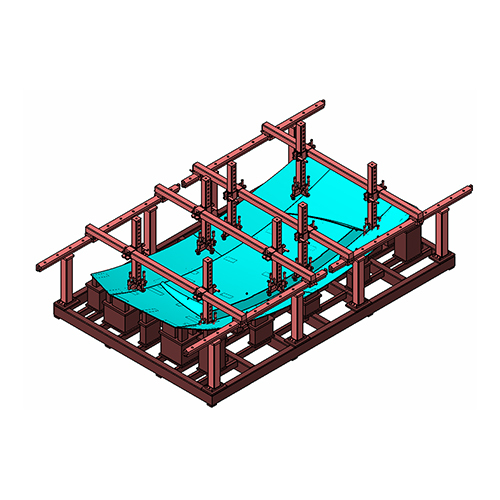

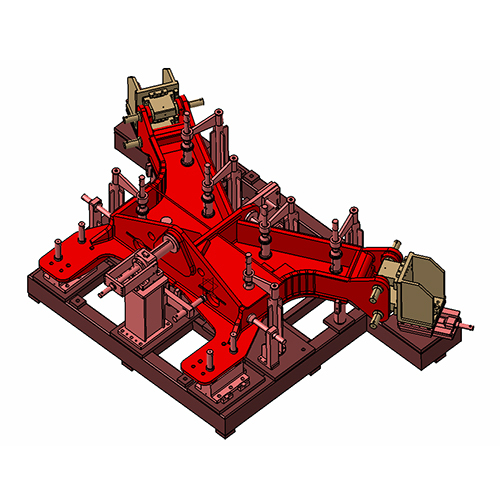

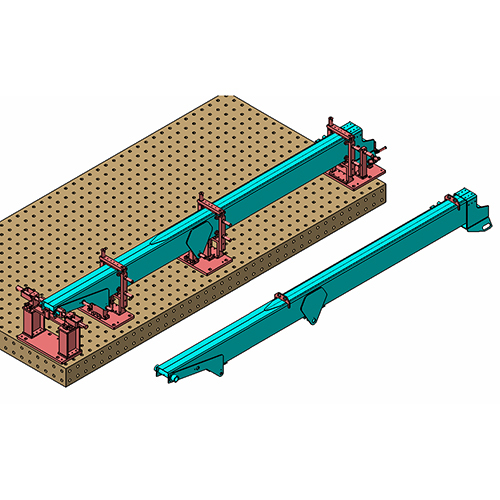

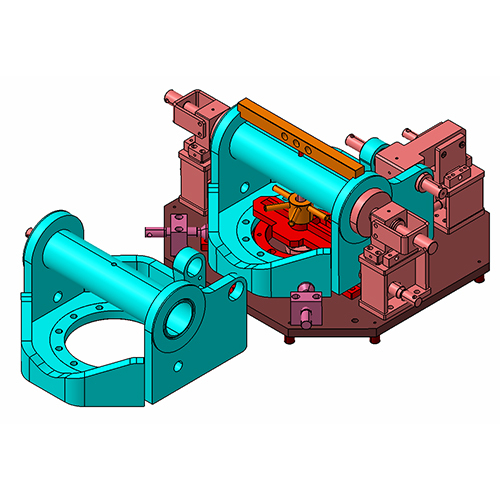

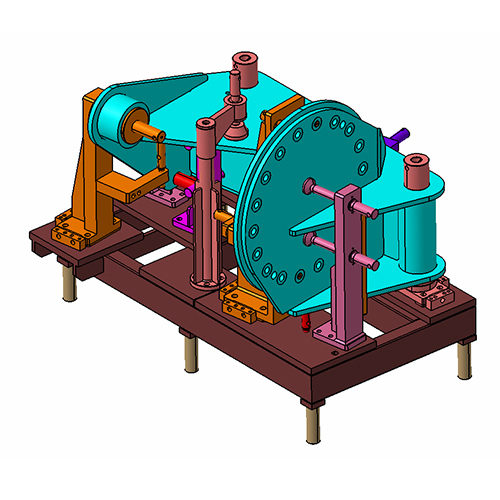

2100SJ Boom and Chassis Tack Welding Fixtures

Price 700000.0 INR/ Unit

MOQ : 1 Unit

2100SJ Boom and Chassis Tack Welding Fixtures Specification

- Operating Voltage

- 230-440 Volt (V)

- Usage

- Industrial

- Material

- Other

- Size

- Standard

- Coating

- Powder coated

2100SJ Boom and Chassis Tack Welding Fixtures Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 20 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- STANDARD

- Main Domestic Market

- All India

- Certifications

- YES

About 2100SJ Boom and Chassis Tack Welding Fixtures

The 2100SJ Boom and Chassis Tack Welding Fixtures are designed to streamline industrial welding processes with precision and efficiency. Crafted from high-quality metal, these fixtures are engineered for robust durability, ensuring reliable performance in demanding environments. The powder-coated finish enhances protection against corrosion, extending the products longevity even in challenging industrial settings. With an operating voltage range between 230-440V, these welding fixtures are highly adaptable to various power setups, catering to diverse operational requirements. Available in standard sizes, the 2100SJ fixtures provide versatility and compatibility across multiple applications, making them a critical component in chassis and boom welding tasks. Designed and fabricated by experts, these fixtures increase productivity, reduce errors, and ensure seamless welding operations for professionals in industrial fabrication tasks.

FAQs of 2100SJ Boom and Chassis Tack Welding Fixtures:

Q: What is the material used for the 2100SJ Boom and Chassis Tack Welding Fixtures?

A: The fixtures are made from high-quality metal designed for durability and robustness.Q: How is the coating on the 2100SJ fixtures beneficial?

A: The powder-coated finish protects against corrosion, ensuring long-lasting performance in industrial environments.Q: What operating voltage do the fixtures support?

A: The fixtures can operate within a voltage range of 230-440 volts, making them versatile for different industrial power setups.Q: What size options are available for the 2100SJ fixtures?

A: The fixtures are available in standard sizes to ensure compatibility with various applications.Q: What is the primary application of these welding fixtures?

A: The 2100SJ fixtures are primarily used for precision tack welding of chassis and booms in industrial fabrication tasks.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Welding Fixtures Category

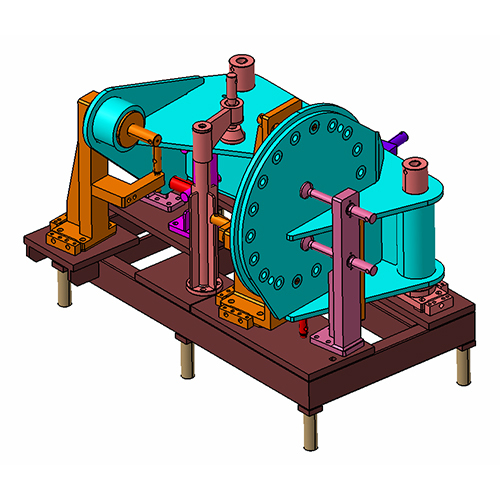

Scissor Chassis Tack Welding Fixture

Price 500000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Coating : Powder coated

Operating Voltage : 230440 Volt (V)

Size : Standard

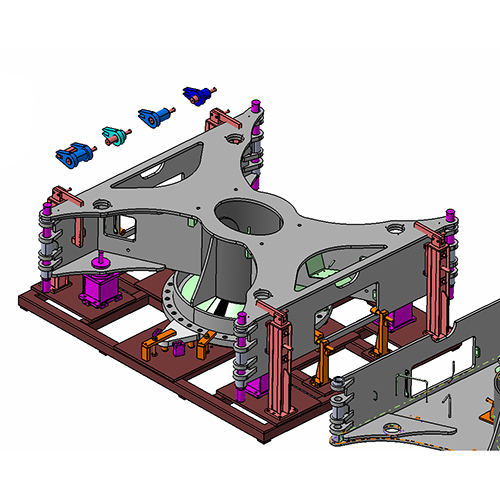

Cunstruction Equipment Tack Welding Fixture

Price 70000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Coating : Coated

Operating Voltage : 230440 Volt (V)

Size : Standard

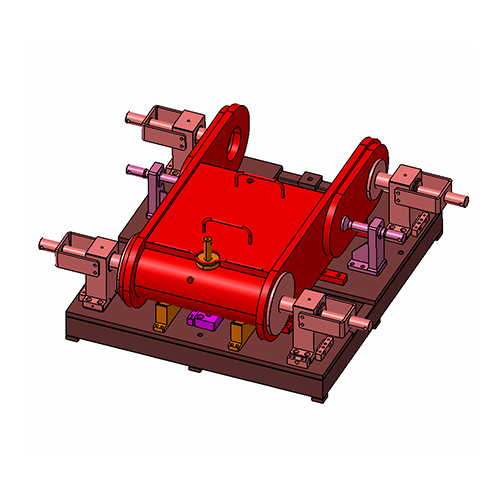

Industrial Cunstruction Equipment Tack Welding Fixture

Price 500000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Coating : Coated

Operating Voltage : 230440 Volt (V)

Size : Standard

Industrial Demller Table Tack Welding Fixtures

Price 600000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Coating : Powder coated

Operating Voltage : 230440 Volt (V)

Size : Standard

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry